Transformation recognizes institutional leadership in high-speed aerodynamics, advanced manufacturing and next-generation flight technologies

The Department of Mechanical and Aerospace Engineering (MAE) at the FAMU-FSU College of Engineering is reaching new heights in aerospace research and education. Driven by cutting-edge grants, state-of-the-art facilities and a spirit of collaboration, MAE is shaping the future of flight and inspiring the next generation of innovators.

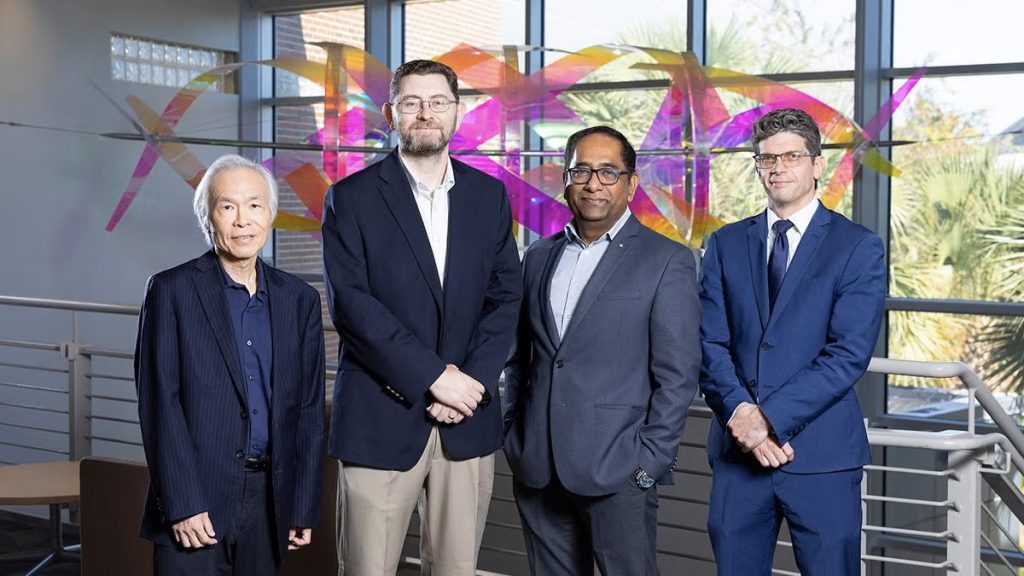

At the heart of this momentum is Rajan Kumar, professor and director of the Florida Center for Advanced Aero-Propulsion (FCAAP). Under his leadership, the MAE department is bridging mechanical engineering with aerospace innovation and opening doors to exciting opportunities for both students and faculty.

Recognition of the Mission with a New Name

Earlier this year, following a comprehensive review and official approval by Florida A&M University and Florida State University, the Department of Mechanical Engineering became the Department of Mechanical and Aerospace Engineering (MAE).

“Having that name is very important for students getting jobs in aerospace and for training them in the areas of interest,” Kumar said. “It will boost our rankings and expand career opportunities for our students, especially in the growing aerospace sector.”

The department’s new name signals a focus on cutting-edge research and education.

“Aerospace engineering is one of the fastest-growing fields in research and graduate education,” said Zhiyong (Richard) Liang, Sprint Eminent Scholar Chair Professor and associate dean for research. “The new MAE department showcases the powerful synergy between our mechanical and aerospace strengths, boosting our visibility and attracting top-tier research and students from around the world.”

This transformation brings with it three graduate programs in aerospace engineering: a non-thesis Master of Science, a thesis-based Master of Science and a Doctor of Philosophy. The department also offers a specialized Aerospace Engineering – Aerodynamics Certificate to ensure undergraduate students have a variety of pathways to launch their careers.

Florida Center for Advanced Aero-Propulsion (FCAAP): A National Research Asset

FCAAP is located in the college’s Aero-Propulsion, Mechatronics and Energy Center devoted to the needs of the highly competitive aerospace industry. Kumar’s group studies things that “move very fast,” — like rockets and aircraft — and the resulting hypersonic flow that you can’t see with the naked eye but has a major impact on performance and noise.

“At FCAAP, we’re powering national programs involving high-speed aerodynamics,” Kumar said. “Our one-of-a-kind polysonic wind tunnel offers testing capabilities you won’t find anywhere else. It spans speeds from Mach 0.2 to Mach 5 — covering subsonic, transonic, supersonic and hypersonic velocities — making it an invaluable resource for groundbreaking research.”

The facility’s several low-speed tunnels are crucial for studying takeoff, landing, automotive and industrial testing. It also features jet labs for studying engine exhaust.

“We focus on the engine exhaust noise and its impact on the aircraft and nearby structures,” Kumar said.

Understanding aerodynamic flow and noise at different speed regimes is critical to aircraft performance and safety. Engine exhaust noise can cause structural fatigue and impact nearby communities, while precise flow control at supersonic and hypersonic velocities is essential for structural integrity and thermal management, making these research capabilities vital for developing quieter, more efficient next-generation aerospace systems.

In recent years, the FAMU partnership in the joint college has begun to pay off for FCAAP as well. Since joint-appointed engineering faculty and their graduate and undergraduate students from both FAMU and FSU work and learn at the center, grants through the HBCU have started to enhance the facility through enhancements and operating expense reallocations. This development opens more bandwidth for future operational and infrastructure expansions.

Leading-Edge Research: Major Federal Investments Drive Innovation

AEROMORPH Center of Excellence

The MAE department recently secured several significant grants, including $5 million that helped launch a university-led AEROMORPH Center of Excellence funded by the Air Force Research Laboratory (AFRL) and the Air Force Office of Scientific Research (AFOSR).

“A little over two years ago, we received a joint grant with the University of Florida from the Air Force Office of Scientific Research,” said Cummins Professor William Oates. “It started with an idea to look at sensors, extreme environments and high-speed aerodynamic applications and turned into something much bigger.”

The consortium allows students, post-docs and faculty to interact with AFRL engineers and scientists to develop technologies for next-generation high-speed flight vehicles.

“There’s a group at Wright Patterson and Eglin collaborating with us on advanced sense-assess-respond functionalities for autonomous aircraft systems,” Oates said. “They are investigating something called physical reservoir computing, where instead of doing artificial intelligence on a computer, you integrate it into a structure. You can put it in the skin of an aircraft and make the aircraft aware of its environment so it can autonomously navigate.”

Hyper-Velocity AFRL Research

Kumar and his team received a $4 million grant from AFRL to establish hyper-velocity research capabilities. This funding will advance air and space vehicle technology and support experimental and computational progress.

“The objective is to develop technologies for next-generation vehicles and to train students in research areas of national interest,” Kumar said.

This grant enables the department to push the boundaries of hypersonic flow diagnostics, invest in cutting-edge equipment and explore new frontiers at ever-higher Mach numbers.

“Hypersonic research is the crucial need in the aerospace industry today,” Kumar said. These advances build on decades of pioneering work within the department.

CISCOR Center: Robotics for Extreme Environments

Jonathan Clark, professor and director of the Center for Intelligent, Systems, Control, and Robotics (CISCOR), is collaborating with mechanical engineering researcher Camilo Ordóñez on underwater robots, funded by a $1.05 million grant from the Office of Naval Research (ONR) to explore the benthic region of the sea floor.

Clark is also involved with a project funded by NASA that examines the development of rovers with the unique ability to traverse lunar terrain.

“We developed a legged platform that can move through fine, powdery lunar regolith, climb steep slopes and walk on the terrain efficiently,” Clark said.

In another project, Associate Professor Christian Hubicki received a grant from L3Harris to develop a hybrid leg/wheeled robot for exploration and IED removal.

“Christian and I are working on new ideas to create robots that can go over rough terrains and reach difficult spots where IEDs might be hiding or hard to reach,” Clark said.

Professor Carl Moore is part of a National Science Foundation-sponsored engineering research center, Human Augmentation via Dexterity (HAND) and that involves five partner universities, including FAMU.

HAND is developing advanced robotic hands that can work alongside humans in real-world settings. The center’s goal is to create versatile robot hands that are easy to use right out of the box, equipped with AI-powered capabilities that improve over time.

These systems feature intuitive controls that workers can operate immediately, making robotic assistance more accessible across industries and in everyday circumstances.

“We want to develop low-cost test beds for teaching and training people dexterity and robotic dexterity,” Moore said. “The idea is to get platforms that don’t cost hundreds and thousands of dollars in people’s hands.”

Computer Modeling: Digital Twins Enable Virtual Aerospace Testing

Several faculty members focus on the computational aspects of aerospace research. Associate Professor Unnikrishnan Sasidharan Nair uses numerical simulations to study aero-propulsion problems, including supersonic inlets and exhaust plumes of high-speed aircraft. His research expands to other fields, like aeroacoustics, noise propagation and hypersonic transition.

“Some things cannot always be done in the wind tunnels,” Nair said. “That’s where computational studies come into the picture.”

Nair and others digitize the tunnel to set up a virtual model that can be simulated. They create something called a digital twin of the tunnel-model system, and it helps them use mathematical equations to solve for millions and billions of spatial features of the flow field around an aircraft to understand what’s happening.

Sustainable Aviation: Zero-Emissions Aircraft Development

Along with several colleagues at the joint college and other commercial and academic partners, Professor Juan Ordóñez is working on a NASA ULI (University Leadership Initiative) grant to develop concepts for an integrated zero emissions aircraft that uses liquid hydrogen both as fuel and as coolant for components of the power train.

His research targets thermal management solutions for advanced power systems and the optimization of renewable energy conversion processes. Thermal management plays an important enabling role in aerospace systems.

“For example, we need innovative thermal management solutions to use large (megawatt-scale) fuel cell systems for commercial aircraft. Renewable energy processes are integral to space exploration. In this context, the new MAE designation reflects well our research direction,” Ordóñez said.

Ultimately, Ordóñez wants to work on projects that have potential to bring innovations to the energy conversion systems we use as a society and at a global scale.

While aerospace applications drive the department’s new identity, the transformation also reflects decades of materials science excellence that underpins advanced aerospace technologies.

The department is home to Professor David Larbalestier and other internationally recognized leaders in superconducting materials, advanced microscopy and materials characterization and more, representing the department’s deep expertise in developing the fundamental materials that enable next-generation propulsion systems, lightweight structures and high-performance aerospace components.

This foundation of materials science with aerospace engineering creates a powerful research ecosystem where fundamental material innovations directly address critical challenges in extreme flight environments, from hypersonic thermal management to advanced electromagnetic systems.

InSPIRE Center: Strategic Regional Partnership for Aerospace Manufacturing

The Institute for Strategic Partnerships in Research and Education (InSPIRE) is an FSU initiative designed to establish a new aerospace and advanced manufacturing hub in Bay County, Florida. The institute is designed to support workforce development, national defense needs and economic growth in the Florida Panhandle. The FAMU-FSU College of Engineering is an InSPIRE strategic partner, serving as an academic hub for faculty and researchers. Eventually, Bay County graduate students will earn advanced aerospace and manufacturing engineering degrees through the joint college while working at the InSPIRE facility.

Farrukh Alvi, a Don Fuqua Eminent Scholar, professor of mechanical engineering and the Senior Associate Provost for Strategic Initiatives and Innovation at Florida State University, is the founding director of FCAAP and played a key role in launching InSPIRE.

Combined, the new degree offerings and the InSPIRE center will only heighten the department’s impact, Kumar said.

Collaboration as the Key to Success

“The FAMU-FSU College of Engineering stands out for its joint structure, drawing students and faculty from both Florida A&M University and Florida State University,” Kumar said, noting that students from both institutions work together in labs and multicultural settings.

This tradition of collaboration extends beyond the institutional partnership to encompass computational and experimental faculty teams, as well as the overlap in mechanical, aerospace and materials science engineering.

The department’s interdisciplinary approach has been foundational to its research centers and laboratories, creating an integrated ecosystem where diverse expertise converges on complex aerospace challenges. Kumar said this collaborative framework, built over decades, formed the essential foundation for the aerospace redesignation and continues to drive the department’s research success.

The commitment to student development remains central to this collaborative mission.

“We are dedicated to hands-on research training and professional development for students,” Chiang Shih, professor and director of the AME Center, said. “Our role is to prepare them for work with organizations like NASA. In the past four years alone, over 28 students have interned there.”

This partnership model extends well beyond the two universities, encompassing a broad network of academic and industry collaborators that amplifies the department’s research capabilities and impact.

“We continue to collaborate with University of Florida, University of Central Florida, Ohio State University, Embry-Riddle Aeronautical University and others, because it’s helpful,” Kumar explains. “We cannot do everything at one institution, but because of these collaborative efforts, we have been very successful.”