Researchers at the FAMU-FSU College of Engineering are improving 3D printing technology by teaching machines to learn from each other.

In a new study published in the IEEE (Institute of Electrical and Electronics Engineers) Transactions on Automation Science and Engineering, researchers showed how data from one printer can be used by other machines to improve efficiency and quality.

“Cloud manufacturing, along with the Internet of Things (IoT), is a newly emerging technology,” said paper co-author Hui Wang, associate professor at the FAMU-FSU College of Engineering. “The technology demonstrates that data generated from multiple production machines can be shared with each in a timely manner, and manufacturing can be enclosed as online services for meeting diverse market demands.”

According to the on-demand manufacturing platform Hubs 2021 3D Printing Trends Report, the global 3D printing market grew by 21 percent in 2020, despite the effects of a worldwide pandemic. This growing industry is accelerating to print everything from metal to biological materials. The race is on to optimize these processes for competitive advantage.

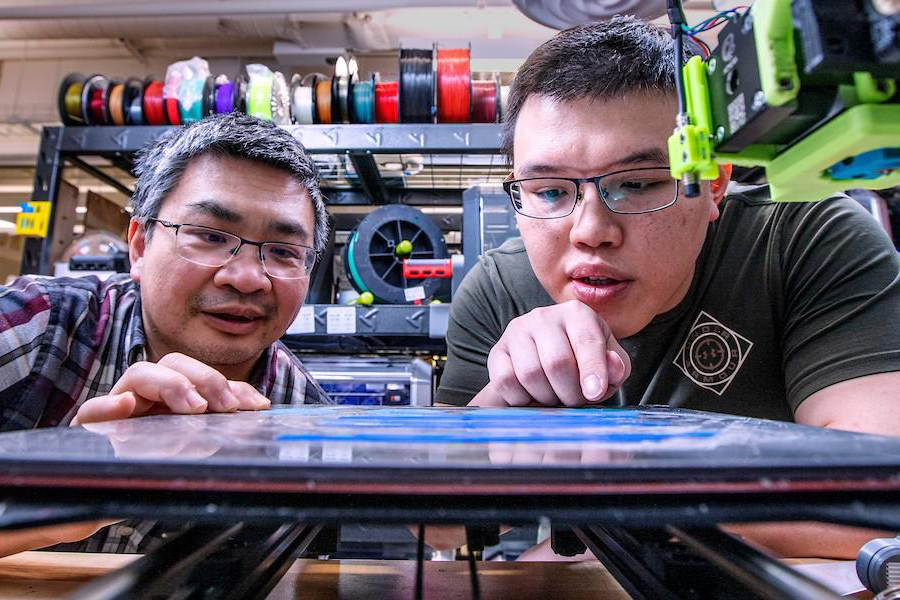

Wang and his colleagues are working to develop new learning algorithms and ways to control the printing process. Tiny differences in the movement of a printer’s nozzle can cause variations in processing and flaws in the finished structure. Their technique uses data shared among machines to reduce printing defects.

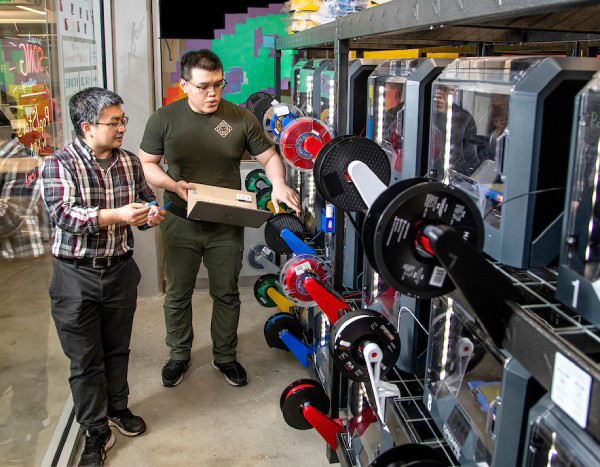

The researchers connected different printers on a cloud platform, and then had the machines share data about accurate processing, which decreased the time needed to prepare and calibrate them.

The researchers also developed a mathematical model to better understand the printing process, said An-Tsun Wei, a doctoral student in the college’s Department of Industrial and Manufacturing Engineering and a paper co-author.

“We can estimate geometric print quality and the related defects that might occur with the model,” she said. “The information can be used to calculate adjustments needed in the input printing parameters to compensate for those errors.”

Traditional machine learning requires a lot of experimental data, which may be difficult to collect. Printers used in manufacturing must be quickly adjusted to cope with new tasks. Transfer learning technology allows different printing processes to share experiences, which speeds up that process. The research demonstrates the feasibility of using historically shared data from interconnected 3D printers to reduce testing time and improve the finished product.

“With reduced testing, we can improve quality control faster and thereby quickly recalibrate the printing processes for meeting diverse market demands,” Wang said. “This is particularly suitable for mass production of personalized products, a manufacturing paradigm envisioned in the future.”

Wang calls this transfer learning a way to achieve “group intelligence” by which multiple learning agents (learners) collaborate to outperform a single learner. The technology can be applied to a variety of products using different materials.

The investigation is partially supported by two grants from the National Science Foundation totaling more than $1.3 million. One engages the NSF’s Research Infrastructure for Science and Engineering program (RISE) and Research Experiences for Undergraduate (REU) at the High-Performance Materials Institute. The platform aims to establish learning methodologies leading to a viable way to create high-performance lightweight composite structures in various size scales. The other NSF grant supports research on flexible manufacturing to meet diverse market demands.