Four Florida State University researchers are receiving grants from the university to take promising research from the lab bench to the global marketplace.

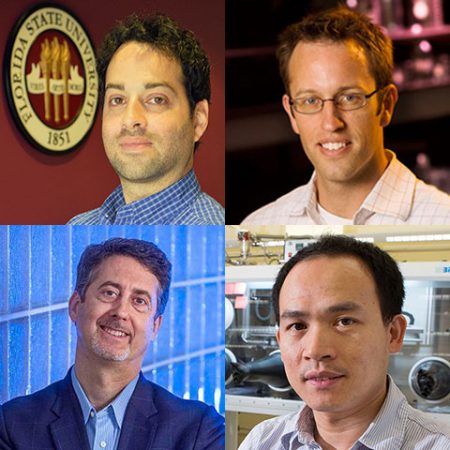

Researchers Yaacov Petscher, Scott Stagg, Joseph Schlenoff and Biwu Ma will receive a combined total of more than $150,000 to work on projects such as creating an application that helps teachers properly group students for instruction and manufacturing a cheaper LED lightbulb.

They received the money through the university’s biannual GAP competition, a “Shark Tank”-like event that allows researchers to pitch their ideas to a panel of local business men and women, Vice President for Research Gary K. Ostrander and Office of Commercialization Director Brent Edington.

“An important part of our mission at FSU is to produce new technologies and make discoveries that can help us better understand the world around us and also make it a better place,” Ostrander said. “The GAP competition lets our researchers pitch their best ideas to help them realize the work’s full potential. The funding we provide can help them move their research to the next stage of development on the road to commercialization.”

The GAP program provides university research with funding to help prepare their work for commercialization and potentially find outside investors. Over the past 10 years, researchers have received more than $2 million to help develop products such as new cancer treatments, food contamination test kits and next-generation wound dressings.

At the fall competition, the panel agreed to fund four promising projects.

The winning projects are:

- An app for teacher planning: Petscher, director of research for the Florida Center for Reading Research at Florida State, has developed a new tool for teachers to quickly analyze students’ testing data and group them according to the skill they need to develop. This would help cut down on teacher planning time and allow them to effectively group students to help provide better instruction.

- Better lab equipment: Stagg, assistant professor of chemistry, developed a new device to prepare samples that are examined under a 3D electron microscope. This new device allows molecular samples to be prepared in reproducible, routine ways without contamination. Stagg hopes to fine-tune the device to bring it closer to a commercially viable product for researchers around the globe using these microscopes.

- Next-generation bandages: Schlenoff, a Robert O. Lawton Distinguished Professor, developed a new material that can completely seal off a wound and ultimately become much firmer than a gauze bandage. It is easily removed with warm saline and does not stick to the wound.

- A better LED lightbulb: Ma, associate professor of chemical and biomedical engineering, is working to develop next-generation phosphorous-based materials to make a higher quality, more affordable and environmentally friendly LED lightbulb.