A remarkable new material that has shown promise in a variety of applications, ranging from lightning strike protection and electromagnetic-interference shielding to the design of next-generation aircraft and computer displays, is bringing international attention to its Florida State University developers.

Researchers with FSU’s High-Performance Materials Institute recently were recognized for their work with engineered carbon nanotube and nanofiber buckypapers, which were named one of the most innovative nanotechnologies of 2007 by the editors of R&D Magazine and the Micro/Nano Newsletter.

“We present the 25 best micro- and nanotechnologies of the year,” the publications stated in introducing the award recipients. “These products, processes and innovations are groundbreaking technologies that are likely to have a large impact on their specific industries and society.”

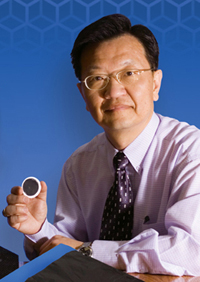

“Many organizations are doing some outstanding work in nanotechnology,” said Ben Wang, research director of the High-Performance Materials Institute and a professor of industrial and manufacturing engineering at the Florida A&M University-Florida State University College of Engineering. “We are honored to have our research recognized among the top 25 in this revolutionary field.”

Already, the technology is being evaluated for existing and new products. Leading companies such as Lockheed Martin and Boeing are considering using buckypapers in aircraft structures.

Wang envisions other commercial applications for the technology in the near future.

“Carbon nanotube and nanofiber buckypapers soon will provide lightweight thermal conductivity to dissipate heat in laptop computers,” he said. “They also will provide electromagnetic-interference shielding in computers and aircraft; offer lightning-strike protection in composite structures such as aircraft or large windmill blades; enhance the strength of composite structures; and be used for embedding sensors in composite materials.”

Farther down the road, Wang foresees applications such as using buckypaper in producing morphing structures and in providing backlight sources for laptops.

Buckypaper is made from carbon nanotubes—amazingly strong fibers about 1/50,000th the diameter of a human hair that were first developed in the early 1990s. It owes its name to Buckminsterfullerene, or Carbon 60—a type of carbon molecule whose powerful atomic bonds make it twice as hard as a diamond. Sir Harold Kroto, now the Francis Eppes Professor of Chemistry at FSU, and two colleagues shared the 1996 Nobel Prize in Chemistry for their discovery of Buckminsterfullerene, whose molecules were nicknamed “buckyballs” for their spherical shape. Their discovery has led to a revolution in the fields of chemistry and materials science–and directly contributed to the development of buckypaper.

In describing FSU’s entry, the Micro/Nano awards stated that “these materials are macroscopic or continuous thin films or membranes comprised of randomly oriented and magnetically aligned CNTs (carbon nanotubes) and nanofibers. These buckypapers combine the advantages of large dimensions, superior electronic conductivity, nanotube alignment, and continuous production.”

Read about all of the “2007 Micro/Nano 25 Award Winners” at www.rdmag.com. To learn more about FSU’s High-Performance Materials Institute, visit www.hpmi.net.