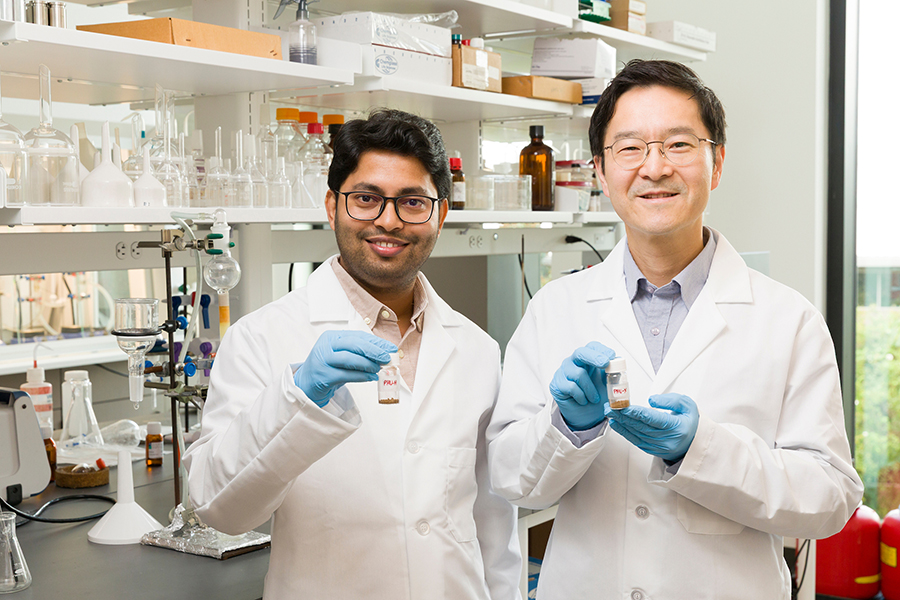

In Ho Yong Chung’s laboratory, magic is at work — plants turn into plastics.

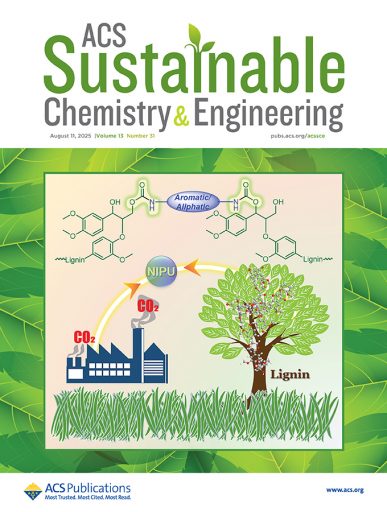

In new research, Chung, an associate professor in the FAMU-FSU College of Engineering, showed for the first time the possibility of using lignin, a material found in plant cell walls, and carbon dioxide to create a new kind of polyurethane, a polymer used in various applications for its ability to regulate heat, flexibility during processing and strength as a finished product.

The work was published in ACS Sustainable Chemistry & Engineering.

“We’ve created a high-quality polymer using fewer steps, less energy and no toxic ingredients,” Chung said. “It’s better for the environment, better for people and easier to manufacture.”

WHAT THEY DID

Traditional polyurethane relies on compounds called isocyanates, which are highly reactive and hazardous. Chung’s method skips them entirely. By using the natural polymer lignin, they created a material that is biodegradable, made from a renewable and underutilized resource and avoids toxic chemicals. Their discovery keeps the benefits of polyurethane but avoids its disadvantages.

Although lignin has some applications in modern manufacturing, it is usually treated as a byproduct of pulp and paper processing.

The breakthrough from Chung’s team creates the same high-performance materials in traditional polyurethanes but uses abundant waste from paper mills and captured carbon dioxide. The resulting material is as strong and heat-resistant as conventional versions but dissolves easily in solvents for manufacturing.

WHY IT MATTERS

The ability to be easily processed gives this material a major advantage over other biomass-based alternatives to petroleum-based plastics.

“Scalability is big for us, because we are a polymer science group and we’re always trying to scale up and commercialize and industrialize our research technology,” Chung said. “This has much better processability compared to other alternatives used to recreate polyurethane. We use far fewer reaction steps to produce the same quality or higher quality of material. That saves a lot of energy, which is good for the environment and for cost and efficiency. We spend less money to produce the same or higher quality of polyurethane.”

LOOKING TO LIGNIN

Chung’s previous research has explored the possibilities for using lignin to make other types of environmentally friendly plastics. In work published in 2024, he showed the possibility of using it to create polycarbonate, material from another polymer family.

This research expands what is possible with lignin by focusing on polyurethane. The polymer’s flexibility and elasticity mean it is more widely used than polycarbonate.

Chung first became interested in lignin in graduate school, when he sought to develop it for use as an adhesive. At the time, there was little research into this material. When he began his career, he continued to focus on it because it offered the possibility of breakthroughs in medical applications, energy and sustainable materials.

“Polyurethane is a very important material,” Chung said. “By producing it with a new and non-toxic method, we can help the world.”

POWERED BY FSU

Chung credited FSU’s support for helping bring this vision to life. With a lab space in the university’s new Interdisciplinary Research and Commercialization Building, access to internal funding and a collaborative network of top-tier scientists, he has been able to push the boundaries of sustainable chemistry.

“FSU gave me the space, the tools and the people to make this happen,” he said.

COLLABORATORS AND FUNDING

Postdoctoral researcher Arijit Ghorai was the lead author of the study. This research was supported by the U.S. Army Research Office and the Ministry of Trade, Industry & Energy of the Republic of Korea.