Researchers at the FAMU-FSU College of Engineering are improving the safety and performance of electric vehicles through a new design that protects their batteries.

Their design uses tubes filled with paraffin wax, which is a type of phase change material, or PCM. These materials are commonly used to store and dissipate heat, making them useful for protecting a battery from overheating.

The researchers’ new method uses PCM-filled tubes in another way, exploring their application as protection against an impact. The work was published in the journal Structures.

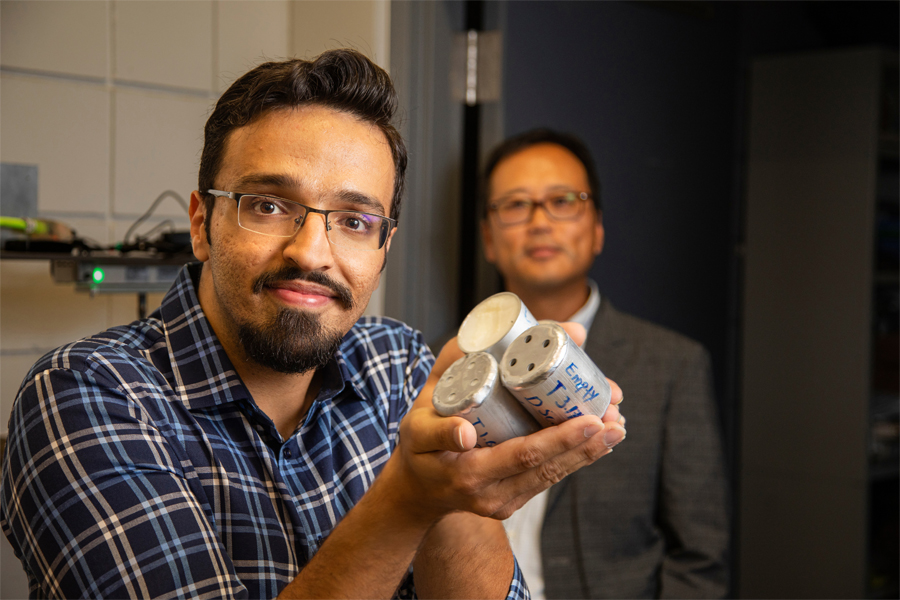

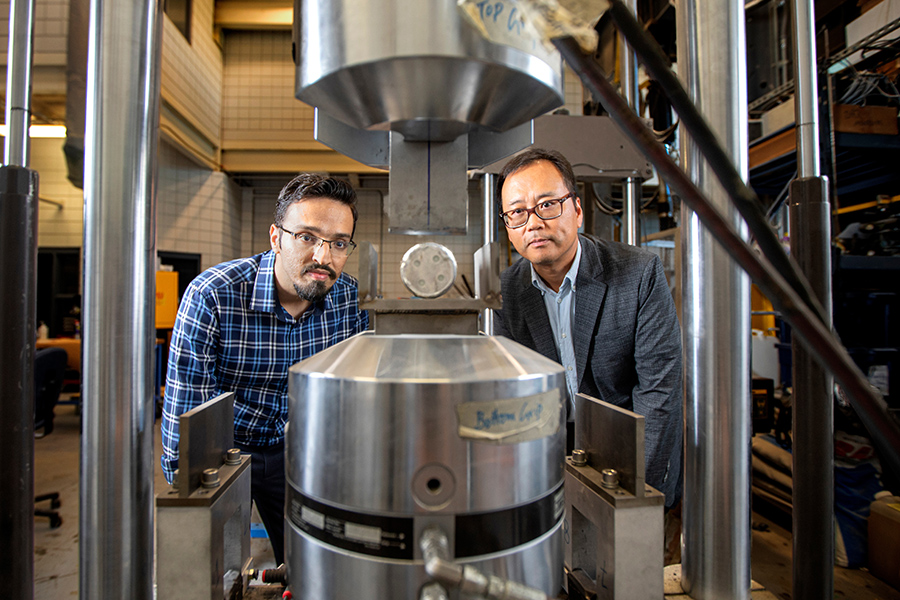

“We want to manage the risk of battery damage in a crash,” said Farhad Farzaneh, a doctoral candidate in the Department of Civil and Environmental Engineering and the study’s lead investigator. “This is a significant concern in the overall safety and reliability of electric vehicles and will help advance their adoption in the automotive industry.”

Crash absorbers should be lightweight and capable of absorbing a significant amount of energy during an accident. The PCM-filled tubes soften the blow from impact and absorb heat, keeping nearby battery cells at a safe temperature and protecting against temperature rise that might lead to a fire.

The research team examined thin-walled aluminum tubes with a range of diameters, thicknesses of exterior metal, and end cap designs. They developed models to predict their performance according to those parameters and verified those models through experiments.

They found that tubes that were capped on their ends and tubes that were filled with PCM absorbed about 43% and 74% more energy, respectively, than unfilled tubes.

“Impact loading on the battery module is a major risk in adopting electric vehicles,” said coauthor Professor Sungmoon Jung. “Of course, every measure you adopt to protect a vehicle has trade-offs for things such as weight. Farhad’s research found an innovative way to combine two protective measures into one to improve the safety of electric vehicles.”

Besides making batteries safer in the event of a crash, the research could indirectly improve battery life by minimizing potential damage from a less intense impact or thermal issues.

“By incorporating PCM-filled tubes in electric vehicle batteries, we hope to prevent catastrophic events and improve the overall reliability and durability of the battery system,” Farzaneh said.