Inside cells there are tiny particles, known as extracellular vesicles, that store and move molecules. Our cells naturally package beneficial proteins and healing compounds into these tiny bubbles, dispatching them to where they are needed to deliver molecular cargo or to communicate with other cells.

Extracellular vesicles, or EVs, are a promising tool for health care because of their ability to contain medicines and to deliver them to hard-to-reach parts of the body. But their benefits are restricted by the challenges of making them at scale.

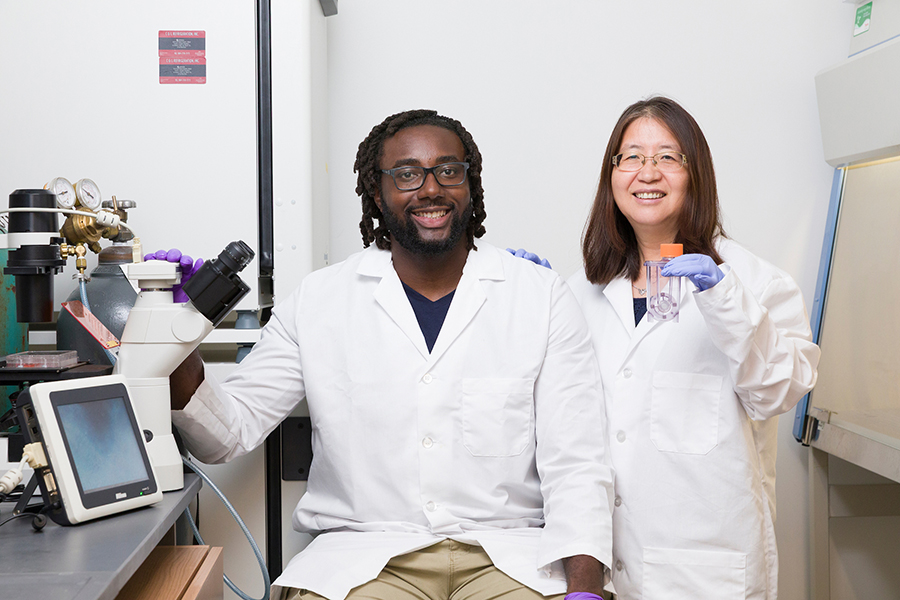

Researchers at the FAMU-FSU College of Engineering have pioneered a method that uses a bioreactor — an industrial device for carrying out biological reactions — with a vertically rotating wheel to mass produce EVs derived from lab-grown blood vessel tissues. This innovation could revolutionize experimental therapies for age-related diseases by making them more affordable and accessible. The work was published in Stem Cell Research & Therapy.

“Imagine if we could harvest microscopic delivery trucks from lab-grown human tissues to carry healing molecules directly to damaged cells in our bodies,” said Professor Yan Li from the Department of Chemical and Biomedical Engineering. “That’s essentially what we have accomplished in our investigation.”

PRODUCTION STRATEGIES

EVs have been limited as a therapy because of the challenge in scaling up their production. Traditional manufacturing methods yield very few of them, making potential treatments expensive.

To address this challenge, the researchers used sophisticated bioreactors known as vertical-wheel bioreactors to create EVs. The spinning chambers within these bioreactors create gentle currents mimicking blood flow in our bodies. This setup helped cells produce 2 to 3 times more EVs compared to the traditional method where the machines just sit still.

“Think of it like the difference between a factory running at normal capacity versus one operating at peak efficiency under optimized conditions,” Li said. “Essentially, the gentle spinning motion enhances both the quantity of these essential vesicles and the overall health of the artificial blood vessels.”

WHY IT MATTERS

The research solves a bottleneck that has prevented EV-based therapies from reaching more patients.

Laboratory tests showed that the EVs produced through this method maintained all their healing properties. They reduced cellular damage from aging and boosted cell growth, key indicators that they retain their therapeutic potential even when produced at larger scales.

By developing a scalable, controlled production method, the researchers have created a pathway for these promising treatments to move from laboratory curiosities to potentially affordable medical interventions for age-related diseases and tissue damage.

“I hope that the research on EVs increases because of our study,” said Justice Ene, a graduate student researcher and study co-author. “In the future, we need to explore the composition of therapeutic cargo and learn how well the research translates to safely being produced at a large scale. There are still many questions, but it’s a step in the right direction.”

COLLABORATION AND SUPPORT

Other FAMU-FSU College of Engineering and Florida State University researchers who were co-authors on this study were Chang Liu, Falak Syed, Li Sun, Danyale Berry, Pradeepraj Durairaj, Zixiang Leonardo Liu and Changchun Zeng. Sunghoon Jung, the executive director of bioprocess research and development at PBS Biotech, which developed the vertical-wheel bioreactors, was also a co-author.

The research is supported by the National Science Foundation (NSF), including the NSF INTERN award, and partially funded by the National Institutes of Health.